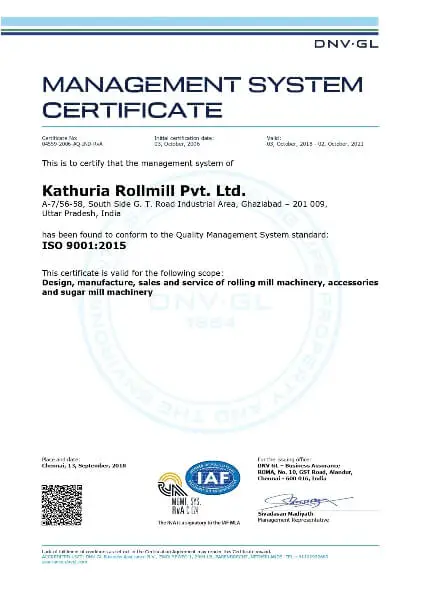

We are an ISO 9001:2015 company. At Kathuria, quality is a continuous endeavour and the quality assurance program we follow is one of the most demanding. We see quality as a direct value-addition and central to the solutions we promise and we go an extra mile to meet both international and domestic standards. The quality cycle that includes evaluation right from the incoming stage continues throughout the process to right upto final inspection and packaging. It is this control at every stage and the comprehensive quality assured by our dedicated QA team that makes our solutions and products score high on reliability.

Testing is ingrained in each process and stage of our manufacturing line. Raw materials undergo stringent metallurgical and dimensional tests. In this process, components receive checks for a variety of standardized parameters and those that do not match are discarded. We have an approach of Total Quality Commitment. The same approach reflects in assembly, testing and commissioning, always.

Kathuria develops its own tools and jigs to expedite manufacturing, assure precision and repeat accuracy. In addition to contributing to ease of use for the shopfloor personnel, this leads to time, labour and cost saving.

Testing is ingrained in each stage of our manufacturing line, from assembly, testing to commissioning. Raw materials undergo stringent metallurgical and dimensional tests. In-process components receive checks against a variety of standardised parameters and those that do not match are discarded. Our zero tolerance policy for faults and focus on “continuous improvement” has helped us deliver equipment of the highest quality to our clients, time and again.