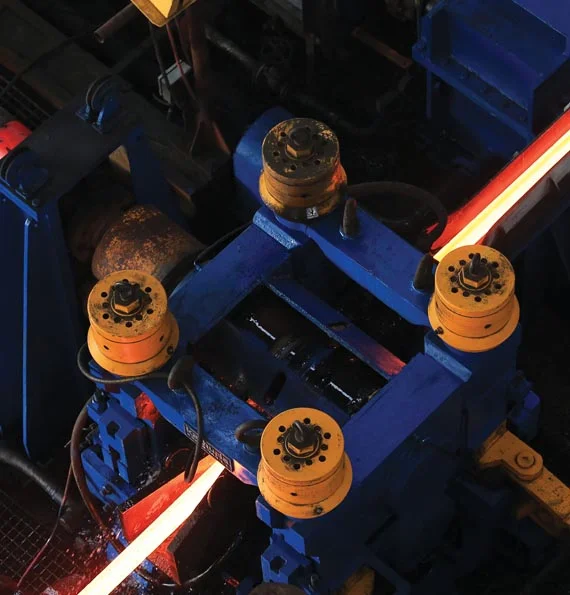

REBAR MILLS

Kathuria is a specialist in high speed bar mills upto 40 m/s to achieve desired production in single as well as in multistrand slit operations. Bar mill operates at relatively low speed in multiple lines, normally consists of 2 to 4 strands, with a common starting material stock. Even though the slit rolling process is employed only for production of rebars, this process is a very economical solution to achieve high rolling production, even for smaller sizes. The annual production may vary, depending on the number of strands, but tonnages in the range of 600,000 Tons Per Year (TPA) can be achieved with product sizes from 8 to 50 mm.

- Reheating furnace and Roughing mill with horizontal-vertical (H-V) stands either of housingless or cantilever design

- Intermediate mill with horizontal-vertical stands (H-V), housingless design

- Finishing mill with horizontal, vertical and convertible stands, housingless design and quick-changing device

- Self-tempering and quenching facilities

- Drop wall roller way with lifting aprons

- Cooling bed Finishing facilities with cold shear, bundling system and wire tying machines

OVERVIEW OF LAYOUT

- Rolling Mill Capacity: Upto 600,000 TPA

- Billet Sizes: 100 x 100 to 160 x 160 mm – 6 to 12 meters

- Finished product: Rebars 8 to 50 mm dia

- Steel grade: Low, medium, high carbon steel

SALIENT FEATURES

MERCHANT MILLS

With the growing requirement of Sections along with TMT bars, the emergence of Merchant Mills is becoming increasingly evident today. Lesser capital investment than two separate mills coupled with minor changes required in the technical parameters of a TMT Bar Mill has made setting up Merchant Mills an attractive option.

WIRE ROD MILLS

Wire rod mills are designed in close cooperation with the plant owners based on the relevant requirements. Single strand high speed wire rod mills roll small sizes with high production capacities up to over 500,000 Tons Per Annum (TPA). Speeds up to 100 m/s are possible and enable high productions for small finishing diameters as well. The thermo-mechanical rolling of wire rod with small dimensions at high production rates is not possible with a conventional 10-stand finishing block. Due to the number of passes required, heating is too high to achieve the required metallurgical properties. Splitting the wire rod block into a 6-stand and a 4-stand unit allows wire rod of any dimensions to be finish-rolled in a maximum of four passes. With sufficient cooling and good temperature equalization over the cross-section, thermo-mechanical rolling at high production rates is also possible.

- Reheating furnace

- Roughing mill and Intermediate mill, with stands of housingless design, in alternating horizontal-vertical (H-V) arrangement, with the possibility of quick-changing device

- Pre-finishing stands of cantilever design

- Finishing block with group/individual drive

- Laying head

- Loop cooling conveyor

- Coil handling system with coil compactor

- Cooling and equalizing line

- 4-stand finishing block with group drive

OVERVIEW OF LAYOUT

- Rolling Mill Capacity: Upto 600,000 TPA

- Billet Sizes: 100 x 100 to 160 x 160 mm – 6 to 12 meters

- Finished product: Rebars & Wire Rod 5.5 to 12 mm dia

- Steel grade: Low, medium, high carbon steel, stainless steel & alloy stee

- LineGarret : 12 to 40 mm dia

SALIENT FEATURES

SECTION/STRUCTURE MILLS

Over a period of more than two decades and demanding market, Kathuria Rollmill has developed to a height to supply section mills encompassing Channels, Angles, Z-section, Flats & Tee. These section mills will be the future of the upcoming era to fulfill the high requirements in the construction industry.

- Special sections and standard sections

- Free entry and continuous feeding layouts

- Top bottom fired re-heating furnace

- Continuous train with universal stands

- Walking beam type cooling bed

- In-line straightening, cantilever or double supported type

- Band saw and Hot saw (fix and movable)

- Automatic stacker & Automatic tying / strapping system

- Automatic Marking Machine

- Weighing and storing area

OVERVIEW OF LAYOUT

- Annual capacity: Upto 600,000 TPA

- Finishing speeds: Upto 14 m/s

- Hexagons 50 - 80 mm

- Angles 25 mm to 150 mm

- Flats 20x 1.5 to 150 x 16 mm

- H-Beams 100 - 180 mm

- I-Beams 100 - 200 mm

- T-sections 75 - 140 mm

- Channels 100 - 200 mm

- Bundle length: 6 - 12 m

- Bundle weight 2 - 5 t